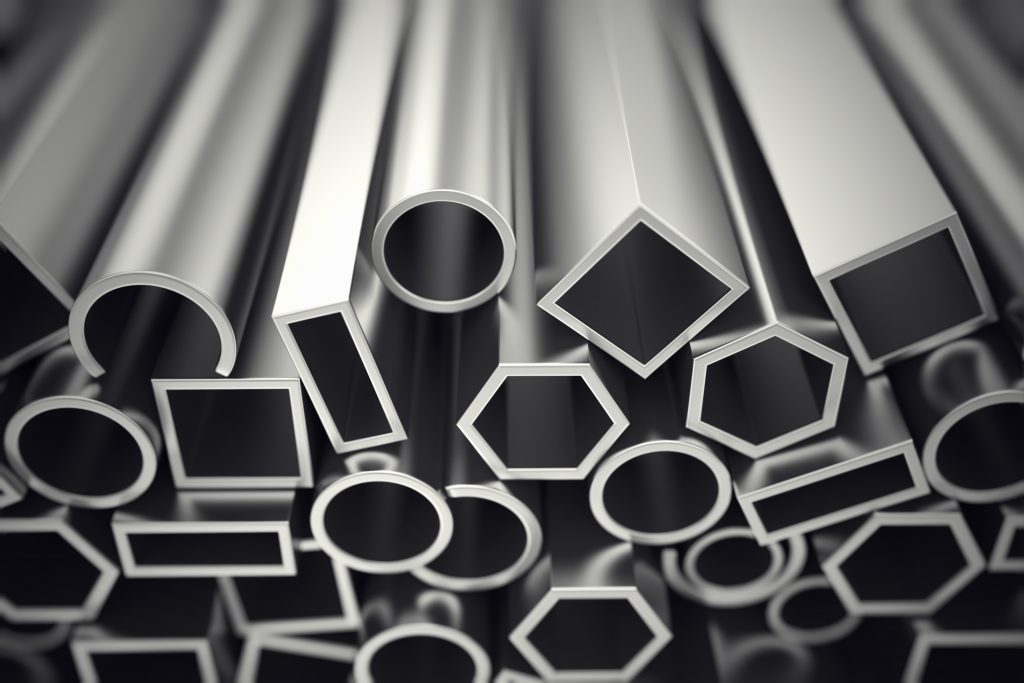

Steel tubes are integral components in various industries, utilized for structural support, fluid conveyance, and mechanical applications. Understanding the different types of steel tubes available helps in selecting the most suitable option for specific needs.

Introduction to Steel Tubes

Steel tubes, also known as steel pipes in certain contexts, are cylindrical structures made from steel, a robust and versatile material known for its strength and durability. These tubes find extensive use across industries due to their ability to withstand high pressures, corrosion resistance, and adaptability to various environments.

Types of Steel Tubes

Steel tubes come in several types, each designed for specific purposes based on their properties and configurations. Here are some common types:

1. Seamless Steel Tubes

Seamless steel tubes are manufactured without welding seams, ensuring uniformity and strength throughout the tube’s length. They are typically used in high-pressure applications where reliability and safety are paramount. Industries such as oil and gas, automotive, and aerospace often rely on seamless tubes for their superior performance under stress.

2. Welded Steel Tubes

Welded steel tubes are made by welding or forging steel plates or coils into cylindrical shapes. They are versatile and cost-effective, suitable for a wide range of applications including construction, machinery, and furniture. Welded tubes vary in size and thickness, catering to different load-bearing capacities and structural requirements.

3. ERW (Electric Resistance Welded) Steel Tubes

ERW steel tubes are produced by cold-forming a steel strip into a cylindrical shape and then passing an electric current through it to create a weld. These tubes are known for their high strength and dimensional accuracy, making them ideal for mechanical and structural applications in industries such as construction and automotive manufacturing.

4. DOM (Drawn Over Mandrel) Steel Tubes

DOM steel tubes are manufactured by cold-drawing a seamless steel tube over a mandrel, which forms the tube’s shape and size. This process enhances the tube’s strength, precision, and surface finish, making it suitable for hydraulic cylinders, shock absorbers, and other precision mechanical components.

5. Galvanized Steel Tubes

Galvanized steel tubes are coated with a protective layer of zinc through a process called galvanization. This coating provides excellent corrosion resistance, making galvanized tubes suitable for outdoor applications and environments prone to moisture and corrosion. They are widely used in construction, agricultural equipment, and fencing.

6. Alloy Steel Tubes

Alloy steel tubes are made from alloyed steels that exhibit enhanced mechanical properties such as strength, hardness, and corrosion resistance. These tubes are tailored for specific industrial applications where standard carbon steel may not suffice. Industries such as petrochemicals, power generation, and aerospace utilize alloy steel tubes for their specialized needs.

Applications of Steel Tubes

Steel tubes serve diverse applications across various industries due to their strength, durability, and versatility. Some common applications include:

- Structural Support: Used in buildings, bridges, and infrastructure projects for their load-bearing capabilities.

- Fluid Conveyance: Transporting liquids and gases in industries like oil and gas, water treatment, and chemical processing.

- Mechanical Components: Forming parts of machinery, vehicles, and equipment due to their ability to withstand mechanical stress.

- Heat Exchangers: Facilitating the transfer of heat in HVAC systems, industrial processes, and refrigeration units.

- Decorative Purposes: Utilized in furniture, interior design, and architectural elements due to their aesthetic appeal and structural integrity.

Conclusion

Understanding the different types of steel tubes enables informed decision-making when selecting materials for specific applications. Whether for structural support, fluid conveyance, mechanical components, or specialized industrial needs, choosing the right type of steel tube ensures optimal performance, durability, and cost-effectiveness in various projects and operations.

By leveraging the strengths and characteristics of each type of steel tube, industries can achieve enhanced efficiency, reliability, and safety in their diverse applications and projects.

For more insightful articles related to this topic, feel free to visit findtec.co.uk