Many individuals confuse corrugated and Cardboard Handle Boxes. Cardboard is used to produce supermarket cereal boxes and folding cartons.

These are suitable for their intended use, however they cannot withstand shipment. Cardboard boxes, built from three layers of fiberboard, can resist shipment.

This blog covers corrugated fiberboard boxes for wholesale shipping box buyers.

Understanding Corrugated Cardboard Handle Boxes’ Paper:

Paper pulp, mostly hardwood, recycled wood chips, and lumber mill shavings, makes corrugated cardboard.

Test paper lines the box’s interior, while kraft paper lines its exterior. Kraft paper costs more than test paper but is better. Virgin chemical pulp from pine, spruce, and fir trees makes it.

Corrugated cardboard is three-layered. fluted corrugated medium between flat liner boards.

The flutes’ rigid arches resist shocks, moisture, and temperature fluctuations. Corrugated boxes are recyclable and can be turned into new boxes.

Small Business Corrugated Boxes Benefits

Small businesses struggle to combine quality and cost. Corrugated boxes are inexpensive and durable.

Corrugated Shipping Crates’ Benefits:

Versatility: Can be shaped to accommodate different goods;

Sustainability: Renewable, recyclable packaging;

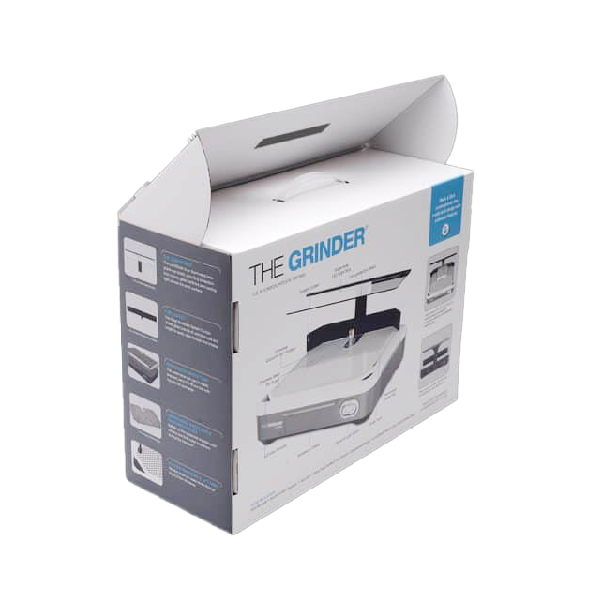

Branding: Kraft Boxes with logos, branding, and marketing messaging boost brand exposure;

Durability: Lightweight, portable, and storeable;

Simple stacking optimizes storage.

A Complete Guide To Corrugated Box Flute Types

Custom Mailer Boxes are what? Three-layer corrugated sheets make a box. Flutes are formed by sandwiching a thin, ridged sheet between two flat sheets.

Corrugation, or C-shaped curls, strengthens fluted cardboard.

A-flute (biggest) through F-flute and lower (micro flutes). Letters indicate order and size.

A-Flute: Applications

A-flute is the original and thickest corrugated flute. Sturdy and pressure-resistant, it protects fragile goods best.

B-Flute Packaging: Advantages And Applications

B-flute features more flutes per foot and a lower arch height than A-flute, offering more liner contact and a rigid, flat surface for printing and die-cutting.

It is puncture- and crush-resistant, takes up less warehouse space, and is suitable for packing canned products, beverage trays, wrap-around blanks, glass-to-glass packs, slip sheets, pads, dividers, and partitions.

High-speed, automated packing processes benefit from B-flute.

C-Flute: Corrugated Boxes’ Most Popular Flute Size

C-flute board makes 80% of corrugated containers. It’s ideal for carrying glass, dairy, and furniture. C-flute is crushproof and stackable.

E-Flute: Thinnest And Most Versatile Corrugated Flute

E-flute can replace paperboard folding cartons for cosmetics, glass, ceramics, and delicate instruments. Its 90 flutes per foot make it crush-resistant and flat for high-quality printing.

F-Flute: The Smallest And Strongest Corrugated Flute

F-flute, a packaging material for small retail items with a lower fiber content, is stronger and stiffer and produces less landfill debris. Fast food companies use F-flute clamshell packaging.

- Corrugated Box Walls: Types and Strengths

- After choosing a flute size, choose a thickness.

- Single-Face Corrugated: Definition and Use

A layer of liner added to a sheet of corrugated media protects fragile items like glass or electronics. This roll-based material helps protect fragile goods.

Single-Wall Corrugated Boxes: Features and Uses

A single-wall cardboard box has two liner sheets and one corrugated board. It is the most ubiquitous cardboard box.

Double-Wall Corrugated: Its Uses And Benefits

The extra layer makes this packaging more sturdy but less flexible than single-wall packaging. POP Displays and packaging use it for extra protection and strength.

Triple-Wall Corrugated: Ultimate Protection And Durability

Three corrugated sheets and four liner board facings make triple-wall custom packaging sturdy and heavy, making it suitable for packing industrial parts or produce containers.

Which Packaging Style Is Right For Your Business?

Boxes should not be overly tight or loose. For varied-sized objects, there are several packing box styles.

Rsc: The Most Common Corrugated Box For Shipping And Storage

A Regular Slotted Container (RSC) contains two equal-sized end panels and two flaps on each side panel that overlap when closed. Tape the flaps.

Full Overlap Container (Fol): Heavy-Duty Packaging and Storage for Bulky Items

FOL containers convey massive, fragile commodities by water. The four overlapping flaps seal and double-walled design provide strength and stability.

One-Piece Folder (Opf): Cost-Effective and Versatile Packaging and Shipping

Retailers use OPF boxes to bundle books, jewelry, and electronics. Products are packaged in a box made from a huge, flat cardboard sheet.

Ftd: Fully Adjustable And Secure Packaging For Unique-Shaped Products

Its double-walled form makes this telescope-shaped container suitable for shipping and storage.

A telescope half-slotted container with a telescoping cover lets you open and close it without taking it off.

Overlap Slotted Container (Osc): Cost-Effective Packaging For Multiple Industries

Adhesives or staples can secure this box shape, which has all flaps the same length and an exterior flap overlap of at least one inch.

Center Special Slotted Container (Cssc): A Reinforced Corrugated Box.

The box’s inner and outer flaps are varied lengths and meet in the center. The double-thick corrugated board on top and bottom makes this type durable. The inside flaps level the goods without gaps.

1-2-3-Bottom Or Auto-Lock Bottom Container (Alb): Convenient And Time-Saving Packaging For Businesses

The bottom panel includes four die-cut flaps for easy assembly. Fold the largest bottom panel, then the two end panels, and press down the last center panel to snap into the slot.

Since the bottom isn’t sealed, it’s best for light loads. Tuck-top flaps, RSC, or other top enclosures are possible.

Wraparound Blank: Eco-Friendly, Customizable Packaging For Unique Products

Automatic equipment folds and seals an unjoined wraparound blank around a stiff product to make a box. This box is an RSC turned on its side with an unbroken bottom and top. Close the box to construct the joint.

Testing Corrugated Boxes For Quality And Reliability

cardboard handle boxes’ weight capacities depend on their strength and structure. Manufacturers test corrugated packaging boxes for strength to help you choose one.

The packaging industry’s most common corrugated box testing procedures are below.

Edge Crush Test (Ect): A Reliable Corrugated Box Compression Strength Test

The Edge Crush Test (ECT) crushes the box by applying force perpendicular to the ridges.

Bursting Test (Mullen): Testing Corrugated Boxes for Safe Shipping and Handling

The Mullen Test, also called the Bursting Strength Test, tests corrugated board wall resistance to force. Hydraulic fluid in a rubber diaphragm breaks corrugated packaging box walls.

Flat Crush Test (Fct): Testing Corrugated Boxes For Pressure Resistance

The Flat Crush Test measures corrugated cardboard’s strength. This test helps digital or offset box printers calculate how much pressure they can safely apply.

Water Absorption Test (Cobb): Corrugated Box Moisture Resistance for Reliable Protection

Corrugated fiberboard absorbs and retains water in the Cobb Sizing test. Depending on quality, a large steel roller squeezes out the water. Hazardous material packaging certifications need this test.

Paper Grammage And Thickness: Corrugated Board Physical Properties For Optimal Packaging

These custom mailer boxes grammage and thickness depend on their use. Since larger flutes fill with more air, thicker boxes provide additional cushioning. Thinner boards with denser flutes require higher grammage boxes for compact and rigid packaging.

Puncture Resistance Test: Testing Corrugated Boxes for Punctures and Tears

Following FEFCO 5 or ISO 3036 standards, corrugated boxes are tested for puncture resistance with a pyramid or triangle weight. These tests examine the box’s transportability by testing its ability to withstand sharp, solid objects.

Scuff Resistance Test: Testing Corrugated Boxes For Abrasion And Friction

Packaging requires printing. The Sutherland Rub Test is the industry standard for coated surfaces like paper, films, paperboard, and printed materials. Rotary abrasion testers and manual wiping can also assess corrugated box abrasion resistance. Pharmaceuticals and medication require scuff resistance tests for label legibility.

Box Compression Test: Essential for Determining Corrugated Box Load-Bearing Capacity

The box compression test, also known as a container compression test, measures a box’s load-bearing capability and distortion before it distorts. Many enterprises carrying huge amounts of custom mailer boxes must test box durability.

Chemical Analysis In Corrugated Box Testing: Material Analysis And Testing For Safe And High-Quality Packaging

Chemical study verifies fiberboard’s suitability. The board’s paper type, moisture, and pH are examined microscopically. This helps comprehend fiberboard and its chemical resistance.

Business Corrugated Boxes: Considerations

Businesses must consider product kind and weight, shipping and handling conditions, environmental impact, cost, customization, and storage and handling requirements when choosing corrugated boxes:

Product Kind And Weight: A box with a thicker flute and stronger design is needed for Heavy or fragile products. Lighter products may need a narrower package.

Shipping And Handling: Distance and shipping mode affect corrugated packaging box strength and durability.

Environmental Impact: Choose recyclable or biodegradable cartons to reduce environmental damage.

Cost: Corrugated boxes should be weighed against product value and delivery needs.

Customization: Printing and branding corrugated boxes can improve consumer experience.

Storage and handling: Are corrugated cardboard handle boxes easy to store and handle?

The Best Corrugated Boxes

This information should help you choose bespoke corrugated packaging boxes. We can assist your business find a packaging manufacturer.

Always secure your belongings throughout transit, and Brandt Box can help with all your corrugated packaging box needs. Request a shipping box quote immediately.