Who invented PLCs?

A lot of people believe that Dick Morley invented the programmable logic controller (PLC). It was crucial for automation and industrial control when he helped General Motors create the first Modicon PLC in 1968.

A programmable controller is an electrical device made for industrial uses. It uses a programmable memory to construct certain solutions, such as logic functions, sequence, timing counts, and arithmetic functions, in order to govern via inputs and outputs.

An essential components of PLC:

- Engine, input, and output modules in the rack should be powered by the power module.

- The central processing unit (CPU) executes sequential, logical, and mathematical operations.

- Module for input and output Both field inputs and field device outputs are handled by it. Wiring is present for devices used as input and output.

- Communication interface module: In one or more racks, the interface module is connected to the I/O modules.

- The PLC rack or chassis is the most important module since it forms the structural foundation of all PLC systems and servers.

Also Read :- Allen Bradley 1766-L32BXB MicroLogix 1400 PLC

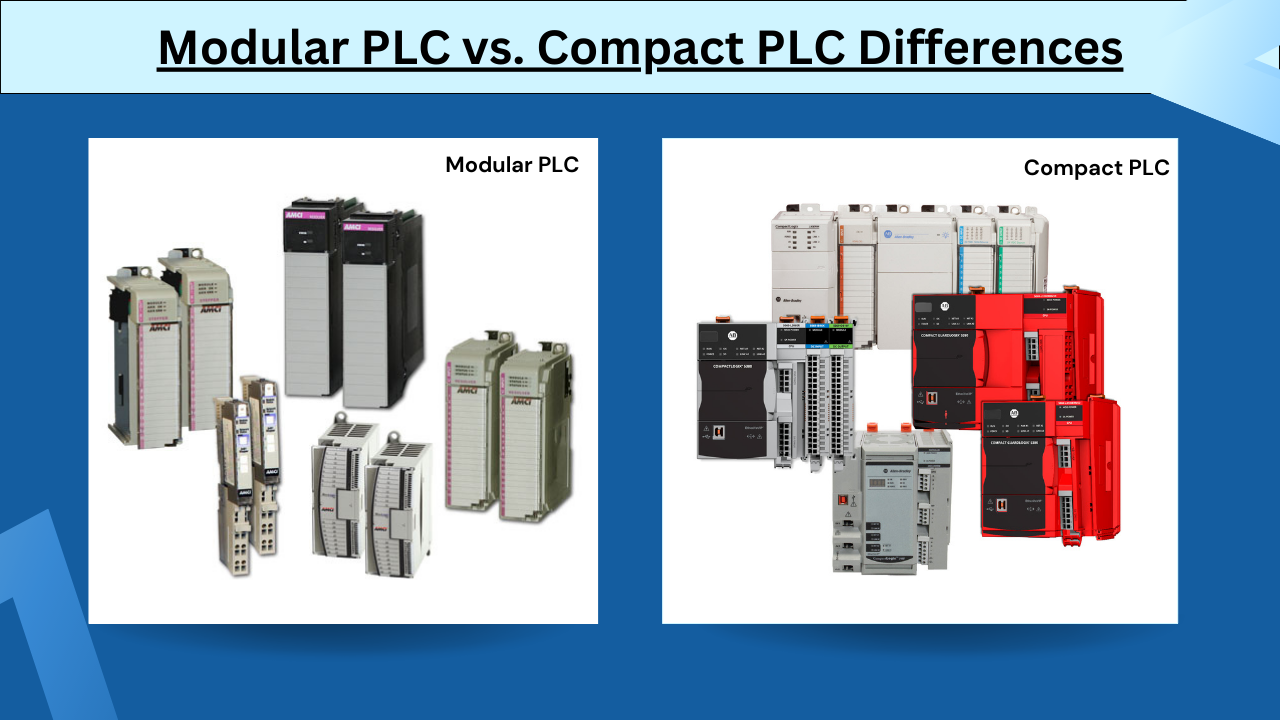

Based on the I/O modules extension facility, there are two different types of PLCs.

- I/O modules in compact PLCs have a set capacity.

- An I/O module’s capacity can be increased; it does not have a predetermined value with a modular PLC.

Let’s first define compact & modular PLC in order to better understand the differences between them.

Compact PLC

A small PLC, also called a fixed or integrated PLC, is a form of programmable logic controller that is made to function as a standalone device with integrated inputs, outputs, and processing power inside of a single container. Its constant I/O configuration, simplicity, and tiny physical size define it. Considerations and important characteristics of compact PLCs are listed below:

- Small Form Factor: Compact PLCs are made to use as little physical space as possible. They are excellent for applications with low space constraints because they are frequently offered in tiny to medium-sized enclosures.

- Integrated I/O: A predetermined number of built-in digital inputs, analogue inputs, digital outputs, and occasionally analogue outputs are included with compact PLCs. These I/O points cannot be increased over the predetermined limit because they are built directly into the PLC unit. The specific small PLC model determines the quantity and types of I/O points.

- Preconfigured Functionality: Compact PLCs are preloaded with a selection of fundamental features and functions, making their installation in common applications easier. They are frequently utilised in applications with fewer I/O points and very simple control requirements.

- Cost-Effectiveness: In general, compact PLCs are more affordable than modular PLCs. Because to their integrated design, fewer additional I/O modules are required, which lowers the system cost as a whole. Their suitability for smaller-scale applications with set requirements results from this.

Modular PLC

Rockwell Automation 1766-L32BXBA MicroLogix 1400 (PLC) that uses a modular rack or chassis and enables the addition or removal of input/output (I/O) modules is known as a modular PLC, often referred to as a rack-based PLC. In comparison to tiny PLCs, it provides more customization, scalability, and flexibility possibilities. The following are some crucial aspects and ideas to remember when using modular PLCs:

- Modular Design: The modular PLC system is made up of a rack or chassis that can hold different I/O module types. These modules fit into slots on the rack, making it simple to alter and increase I/O capacity. A central processing unit (CPU) module and a power supply module may also be included in the rack.

- Flexible I/O Configuration: I/O modules for digital inputs, digital outputs, analogue inputs, analogue outputs, specialised modules (such high-speed counters, communication modules and more) are all available in modular PLCs. According to their application requirements, users can select the precise types and numbers of I/O modules, enabling highly customised and bespoke solutions.

- Scalability: The scalability of modular PLCs is one of its key benefits. Additional I/O modules can be simply added to the rack as an application’s I/O needs alter or expand. Future expansions and alterations are possible because to its scalability without the requirement for major system replacement or reconfiguration.

- High I/O Capacity: Comparatively speaking, modular PLCs have more I/O capacity than compact PLCs. The size of the rack and the particular PLC model determine how many I/O points can be supported. As a result, applications requiring a sizable number of I/O ports and large-scale or intricate control systems are appropriate for modular PLCs.

- Customization and Flexibility: Users have more customization and flexibility possibilities because to modular PLCs. Users can choose features like communication protocols, memory capacity, processing speed, and programming possibilities in addition to the types and numbers of I/O modules. Additionally, how to recover hidden files from usb hard disk some operating systems and software hide system files and folders by default for protection. Because of its adaptability, the system can be customised to meet any application’s particular requirements.

In conclusion, modular PLCs are appropriate for larger-scale applications because they offer flexibility, scalability, and customization choices. Compact PLCs are appropriate for smaller-scale applications with fewer I/O ports since they are straightforward, economical, and simple to use. The specific needs of the application, the necessity for scalability, the preference for customisation, and the budgetary constraints all play a role in the decision between modular and compact PLCs.

We are Asteam Techno Solutions Pvt Ltd: the go-to company for industrial automation products. We make a contribution to the circular economy by providing all industrial automation products for businesses and factories and also providing service work for them. We provide automation solutions with reputed brands including Allen Bradley, Mitsubishi, Phoenix Contact, Siemens, Schneider, Moxa, VIPA and more. This will make it easier to how to recover files deleted from scandisk find the files in the recovery process. Currently our staff members are serve a growing number of national and international customers each day.