The Digital Twin IoT platform addresses a huge achievement in the development of IoT innovation. By spanning the physical and virtual universes, advanced offer remarkable experiences, productivity gains, and open doors for development across businesses. As associations keep on embracing this innovation, we can hope to observe further headways. In today’s interconnected world, the Internet of Things (IoT) has emerged as a transformative force, connecting devices and enabling seamless data exchange. Amidst this technological revolution, one concept that has gained significant traction is the Digital Twin, an innovative approach that combines physical and virtual worlds. This article delves into the realm of Digital Twin an IoT platform and explores its potential to reshape industries, optimize operations, and unlock new avenues for innovation.

What are Digital Twins?

Digital twins are virtual replicas or digital counterparts of physical assets, processes, or systems. They provide real-time insights and predictive analytics by integrating data from sensors, devices, and other sources. These virtual replicas simulate the behavior and performance of their physical counterparts, allowing businesses to gain valuable insights, optimize operations, and improve decision-making processes.

Harnessing the Power of IoT Platforms:

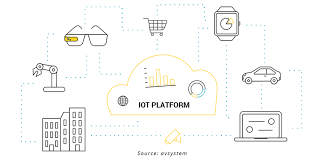

IoT platforms serve as the backbone for digital twin implementations. These platforms provide the infrastructure and tools to connect physical assets to their digital counterparts and facilitate data collection, analysis, and visualization. By leveraging IoT platforms, organizations can unlock the following benefits:

- Real-Time Monitoring and Predictive Analytics:

Digital twins powered by IoT platforms enable real-time monitoring of assets, systems, or processes. This constant data stream allows organizations to detect anomalies, identify potential issues, and make data-driven decisions to optimize performance. Predictive analytics algorithms can analyze historical and real-time data, enabling businesses to anticipate maintenance needs, improve reliability, and minimize downtime.

2. Remote Management and Control:

IoT platforms equipped with digital twins allow organizations to remotely manage and control their physical assets. This capability proves invaluable in scenarios where physical access is limited or unsafe. Through the virtual representation of assets, businesses can monitor and adjust settings, diagnose issues, and even simulate different operating conditions without needing physical intervention.

3.Simulation and Testing:

Digital twins facilitate the simulation and testing of scenarios that would otherwise be costly, time-consuming, or risky in the physical world. Organizations can virtually replicate various conditions, explore potential optimizations, and evaluate the impact of changes before implementing them in the physical environment. This capability empowers businesses to make informed decisions, reduce risks, and optimize resource allocation.

Understanding Digital Twin

A Digital Twin IoT Platform is a virtual replica or representation of a physical object, system, or process. It encompasses the tangible and intangible aspects of the physical entity, capturing it’s

Characteristics, behavior, and interactions in a digital environment. This virtual counterpart is created by continuously collecting and integrating real-time data from various sensors, devices, and systems, allowing for a dynamic and evolving representation.

The Digital Twin framework goes beyond mere visualization. It leverages advanced technologies such as artificial intelligence (AI), machine learning (ML), and big data analytics to simulate and accurately predict the physical entity’s behavior. It enables organizations to gain valuable insights, make informed decisions, and optimize real-time performance

3. Transforming Industries:

Integrating digital twins with IoT platforms transforms various industries, revolutionizing their operations and driving innovation. Some notable examples include:

- Manufacturing:

Digital twins enable manufacturers to optimize production processes, reduce downtime, and improve product quality. Real-time data from IoT devices helps identify bottlenecks, streamline workflows, and implement predictive maintenance strategies. Manufacturers can leverage digital twins to simulate product variations, assess production line efficiency, and enhance supply chain management.

- Healthcare:

In the healthcare sector, digital twins allow for the modeling and simulating of patients’ physiological conditions. It enables personalized treatment plans, optimized resource allocation, and remote patient monitoring. IoT platforms and digital twins enhance patient care, allow telemedicine services, and support medical research and development.

- Smart Cities:

Digital twins integrated with IoT platforms facilitate the creation of smart city solutions. By replicating urban infrastructure and systems, city planners can optimize resource utilization, enhance public safety, and improve traffic management. Digital twins enable the simulation of energy consumption patterns, waste management strategies, and urban planning initiatives, leading to sustainable and efficient cities.

Key Components and Functionality

A Digital Twin IoT platform comprises several vital components that harmonize to deliver comprehensive functionality. These components include:

Data Acquisition: Sensors, actuators, and IoT devices capture data from the physical entity and transmit it to the Digital Twin platform. This data includes temperature, pressure, location, and other relevant metrics.

- Data Integration and Processing:

The platform integrates and processes the incoming data, combining it with contextual information to create a holistic view of the physical entity. This step involves cleaning, aggregating, and analyzing the data to extract meaningful insights.

- Visualization and Interaction:

The Digital Twin platform provides intuitive visual interfaces, enabling users to interact with the virtual representation. It includes monitoring real-time data, exploring historical trends, and accessing analytical tools for deeper analysis.

3Analytics and Predictive Capabilities:

The platform performs advanced analytics on the data collected by leveraging AI and ML algorithms. It can identify patterns, anomalies, and correlations, enabling predictive maintenance, optimization, and decision-making.

Conclusion:

The Digital Twin IoT platform represents a significant milestone in the evolution of IoT technology. By bridging the physical and virtual worlds, digital twins offer unprecedented insights, efficiency gains, and opportunities for innovation across industries. As organizations continue to embrace this technology, we can expect to witness further advancements.

The concept of digital twins, powered by IoT platforms, is reshaping industries across the globe. By leveraging the real-time insights, predictive analytics, and simulation capabilities of digital twins, businesses can optimize their operations, improve decision-making processes, and unlock new levels of efficiency.

Keep exploring!

“I recently hired an agency in Briansclub and they helped me achieve my Briansclubcm.co online goals and improve my website’s visibility. I highly recommend them